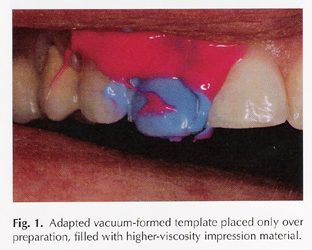

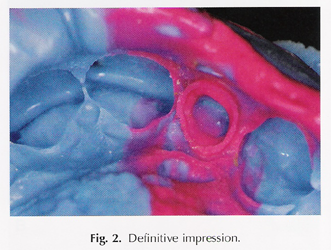

A Simplified Custom Impression TechniqueSteven J. Sadowsky, DDS The use of a custome impression tray has long been recommended for improved accuracy of elastomeric impression materials. (1-3) Finger (4) noted that a thick layerof addition-polymerizing silicone causes distortion ofthe impression material because of the relatively high thermal coefficient. Eames et al (5) evaluated the effect of bulk on accuracy and demonstrated that the interface space of 2 mm produced the most accurate impressions when compared with larger spaces. Autopolmerizing acrylic resin, thermoplasic resin, and light-polymerized acrylic resins have all been used to fabricate custom impression trays to limit the bulkof impression material. The 2-step, 2-mm relief space putty-wash impression technique was also shown to be an accurate alternative method for fabricating stone dies. (6) However, these techniques require additional materials and expense. Clear plastic matrices are routinely fabricated in preparation for fixed prosthodontic treatment. In fact, Preston (7) described the multiple benefits of using a polypropylene matrix, which included guides for esthetic control, waxing, preparation, and both the trial and definitive restoration. This article describes the use of such a matrix to dodify a stock tray, precluding the need for a custom tray or putty-wash system. |

|

|

|

|

| PROCEDURE

REFERENCES

Copyright © 2005 by The Editorial Council of The Journal of Prostetic Dentistry. 2005;94:468-9 Reprinted with premission from Steven J. Sadowsky, DDS |

|