services

Unmatched Accuracy

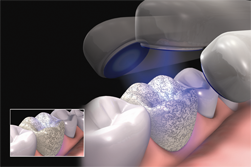

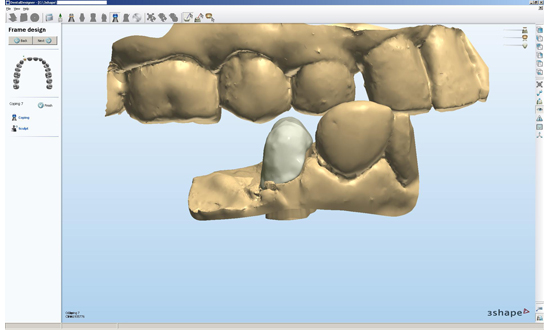

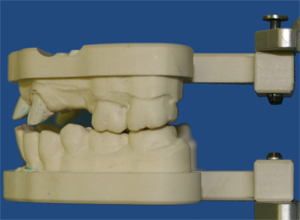

MegabytesDDS™ further complements the digital impression systems with proprietary milling technologies to provide you with a crown or fixed partial denture that has precise interior fit and outer shape. All occlusal surfaces on all types of crowns are fabricated by CAD/CAM technology to optimize occlusal contacts. After receiving, you simply seat the crown or bridge with near zero adjustments needed, saving aggravating seating appointments or time-consuming remakes.

Why Digital Impressions?

An accurate model for an accurate crown - It is critical that the model be an accurate representation of the mouth in order to create restorations that fit correctly. This is partially the responsibility of the dentist to provide accurate impressions. A study, published in the August 2005 edition of the Journal of Prosthetic Dentistry,

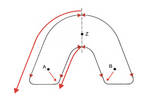

With conventional pin models (on a plaster base), several types of expansion act simultaneously. Firstly, when fabricating arch-shaped models, the plaster's linear expansion in the distal areas is approximately three times greater than in the mesial areas. This results in serious dimensional changes. Secondly, plaster expansion during subsequent fabrication of the plaster base (full model) progresses uniformly and three-dimensionally from the center of the model outwards, and thus has an additional effect on the pin model, in this case a negative effect.

|

|

|

Dental arch |

Plaster Base (full model) |

Dental arch on the plaster base |

(Wilhelm H. Kiefer: "Mit Grips an den Gips" published by Quintessenz Verlag)

Two types of digital imaging principles are currently available in the dental industry—parallel confocal and triangulation/sampling.

CEREC, E4D, LAVA COS

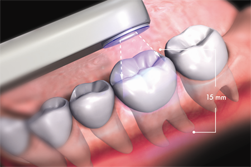

• Scanners that use the triangulation/sampling principle of imaging, typically apply one angled cone of light to capture a single image at 15,000 microns.

• Triangulation/sampling scanners require the teeth to be coated with expensive and cumbersome scanning powder.

CEREC and E4D

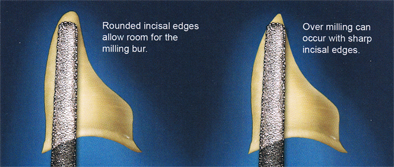

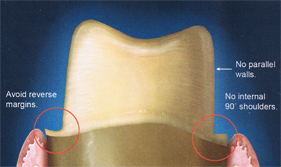

The dentist must learn how to run the milling machine and how to prepare the tooth that will allow the machine to produce a useful restoration.

• Limited to materials available for use with the machine.

• Solid block of material has limited application.

• Powdering the surface reduces the accuracy.

iTero

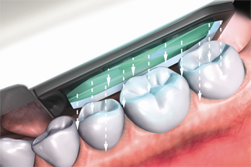

• Cadent iTero features parallel confocal imaging, which utilizes laser and optical scanning to digitally capture the surface and contours of the tooth and gum structure.

• The iTero scanner captures 100,000 points of laser light in perfect focus at 300 focal depths of the tooth structure. These focal depth images are spaced approximately 50 microns apart.

• Parallel confocal scanning with the iTero system captures all elements and materials found in the mouth without the need for scanning powder. Because there is no tooth coating, the iTero system can operate with contact scanning techniques.

• These unique features of confocal scanning enable iTero to capture both supragingival and subgingival preparations.

• Shoulder, chamfer, and feather edge preparations designs can be utilized both supragingival and subgingival.

• iTero digital impression system is capable of full-arch impressions.

iTero:

- “Having looked at all four systems, iTero has the fastest learning curve!”

- “The clearance tabs on the iTero are my favorite feature. It shows the amount of interocclusal clearance on my preparations, allowing me to make changes to the preparation before sending if off to the lab … say goodbye to reduction copings!”

- “Love the voice prompter… it tells you what to do next."

- THE DENTAL ADVISOR

August-September 2009

Volume 26, No. 07

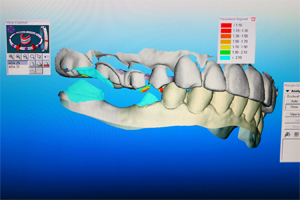

Real-time, Digital Display - Heading Off Problems Before They Arise

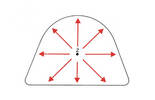

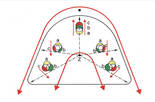

The visualization of the tooth prep area is one of the most lauded benefits of digital impression systems. Dentists visualize and analyze the prep area from a full 360 degrees. Analytical tools are also available allowing you to measure and verify proper occlusal reduction for example. All of which leads to better fitting prosthetics and reduced adjustment time for increased patient satisfaction.

• See magnified 360° views to check for parallelism.

• View on screen color coded occlusal clearance.

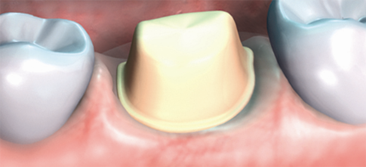

An accurate model for an accurate crown - It is critical that the model be an accurate representation of the mouth in order to create restorations that fit correctly. With digital impressions an accurate model is not a matter of guess work. iTero, without the use of powder that adds inaccuracies to other digital systems, provides a perfect representation of the mouth. Thus guaranteeing that if it fits on the model it will not rock in the mouth.

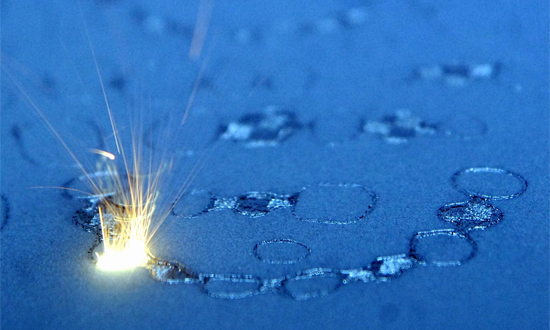

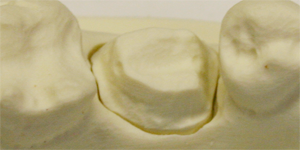

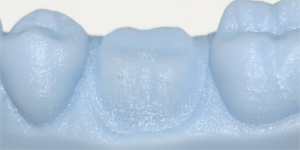

Not only is iTero the only system that does not use any powder. It is the only system to fabricate its models by high precision 5-Axis milling machines. Lava COS models and the CEREC AC's physical model are both fabricated using stereolithography, an additive fabrication process building the model one layer at a time. This produces a stepped surface, as shown in fig. 3 , rather than a smooth one, leaving potential gaps along critical areas such as the margin. |

|

Fig. 3 LAVA COS -

Fig. 3 LAVA COS -